About Us

With a vision of being the best in category Wristbands House operating its brilliant team with uncompromising mission of being the modest and service focused every day. Technologically oriented Wristbands House is engaged with its mission plan to get ease on its processes and the service its deliver now and next. Wristbands House is well focused in using technological advantages, so it is powered by FactoryDox- a powerful platform for B2B operations.

With around 400 Plus employees, Wristbands House is creating value over production and your order that serves your purposes the best.

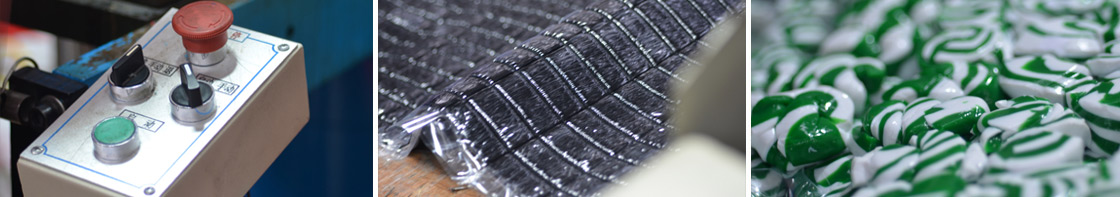

Cutting edge technology for production, creative team comprised of art directors and desktop publishers, IT professionals and dedicated sales and service team are resources of Wristbands House.

Production

Wrisbands House has mainly 3 lines of production. One is for silicone products such as silicone wristbands, silicone keychains, silicone thumb bands and other types of bands. Other is for koozie and one more is for lanyards.

Custom Silicone Wristbands Unit

| Silicone wristbands unit has sub units,as this is a critical line. The band you wear on your wrist is a product comes after a chain of seamless production process. |

Raw Material Process Unit

| Wristbands House uses 100% Eco-Friendly silicone as its raw material. From the colorless compound, raw silicone gets stunning colors, shades, swirl and segmentation at raw material process unit. It includes process like mixing and cutting silicone at right size, shape and color. |

|

Mold Making Unit

Wristbandshouse makes wristbands with molds made of stainless steel and other metals. These molds give your bands the finest edges and shapes. Computerized numeric controlled machines help to get us molds that make designs on bands smooth and clean with details.

Pressing Unit

This unit is made of our hardcore team members as this is the toughest job to be done. Making a band needs 250+/- Degree tempera-ture and 2500+/- Pascal pressure, so we have the toughest teammates there to get your bands at right shape. This unit confirms you the band you ordered would be the nice one with your expected specification.

Crafting Unit

| Custom printing and inkfilling on bands is the major concern of this unit. Wristbandshouse has automated screen printing machine which can print single colors on bands. We have multicolor pad printing machines as well; with this multicolor printing are possible on silicone wristbands. This machine can print at least 6 colors on your band. So, our printing team has unique experience and knowledge on printing over silicone and tyvek. Detail logo and text printing is their key expertise. Along with this we have inkfilling unit which fills your debossed bands with right color of your choice. |

Packaging and Shipping Unit

| Wristbandshouse has a dedicated packaging and shipping team which ensures the right packaging and dispatching to your address. This team uses modern equipment for quality and quantity check. Computerized shipping labeling also used for commercial invoices. |

|

Classical Screen Printing

|

Wristbandshouse has a unit that produce screen print on your products. Screen printing requires few steps to be done before we see nicely printed products. Making the right silk screen is an art. It needs to find the best texture for silks and project the silk in right light exposure to get the best film. This unit has expertise to come up with great quality films for silk screening. |